The masonry wall panel element allows you to easily model, analyze and design masonry walls for in plane

Here we will explain the calculation concepts and code references used in the program. For general wall panel information, see the Wall Panels topic. For information on masonry design rules, see the Masonry Wall - Design Rules (this is where you can define block thickness and self-weight). For masonry wall modeling procedures, see the Masonry Wall - Modeling topic. For masonry wall results interpretation, see the Masonry Wall Results topic.

Note:

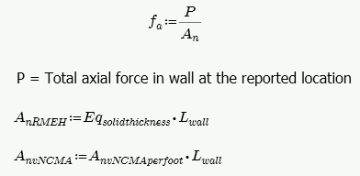

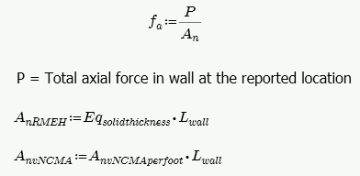

The axial stress in a wall due to axial forces, fa, is calculated as:

This is applicable for all out of plane masonry calculations.

Note:

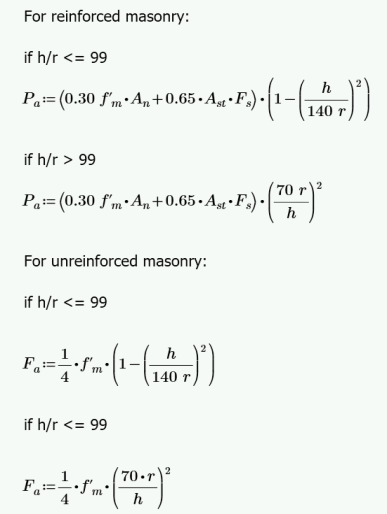

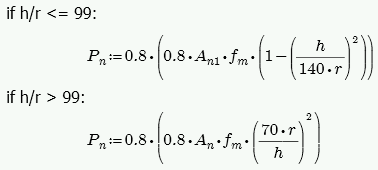

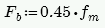

The calculation of Pa for reinforced masonry is Equation 8-16 or 8-17 and Fa for unreinforced masonry is per either Equation 8-11 or 8-12, depending on the h/r ratio. The equations are as follows:

where:

Note:

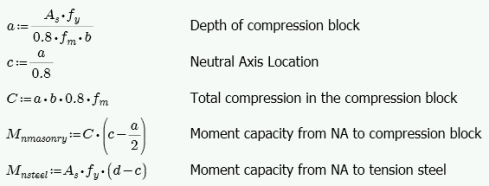

This is calculated from Equations 9-13 and 9-14:

Note:

Note:

The maximum usable masonry strain at the extreme compression fiber, emu, is assumed to be 0.0025. For assumptions of the extreme compression fiber for Seismic Detailing checks of Masonry Walls, refer to the Maximum Area of Flexural Tensile Reinforcement (Max. Flexural Rho Check - Strength) section.

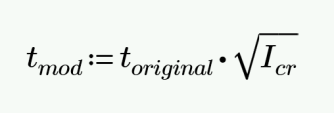

Out of plane deflections are calculated based on the Wall's Finite Element Analysis using a modified thickness, tmod, for the wall plates. The modified thickness is calculated using the wall panel's out of plate cracked moment of inertia, Icr, which can be input in the Advanced tab of the Wall Panels spreadsheet.

Note:

The original thickness of the wall panel is the actual thickness of the wall panel, not to be confused with the nominal thickness.

RISA-3D then uses Finite Element Analysis using the modified thickness of the plates to calculate the out of plane deflection of the wall.

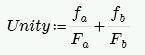

For out of plane design for axial and bending the program performs 3 checks: a compression check, a tension check, and a slenderness check.

where:

Here we will talk about specific calculations regarding lintel design for allowable stress design.

Note:

This stress is calculated from Equation 8-19:

where:

The program calculates the capacity, Fv, from Equation 8-25, which is shown in the previous In Plane Shear Capacity Fv section.

The program also checks to verify we do not exceed the Fv max value from Equations 8-21 and 8-22 (or interpolation between them) that is reported in the detail report.

Fvs is only required if fv > Fvm. If fv < Fvm, then the program will not add any shear reinforcement and Fvs = 0. If Fvs is required, then the program will back calculate a spacing, s, that will satisfy the steel shear capacity required. This shear spacing is reported in the detail report.

When shear reinforcement is required the program will also meet the d/2 or 48" spacing required by 8.3.5.2.1. If Fv max must be exceeded to pass the code check, the program will use Fv max as the capacity and state "Over Allowable" for the Shear Steel Spacing.

Note:

The bond stress check is one that has been grandfathered in from the UBC-1997 specification section 2107.2.16 and is defined previously in the In Plane Bond Stress u section. Σo is the summation of the circumference of all vertical bars.

The bond stress capacity was defined previously in the Bond Stress Capacity U section.

The masonry bending stresses were defined previously in the Out of Plane Stresses fb and fs section.

Section 8.3.4.2.2 states:

Section 8.3.3.1 defines the allowable steel stress, Fs.

Here we will talk about specific calculations regarding lintel design for strength design.

Note:

The program calculates the capacity, Vn, total from Equation 9-15, which was shown previously in the In Plane Shear Strength Vn section.

The program also checks to verify the Vn max value from Equations 9-16 and 9-17 (or interpolation between them) that is reported in the detail report is not exceeded.

Vn,steel is only required if Vu > Phi*Vn,masonry. If Vu < Phi*Vn,masonry, then the program will not add any shear reinforcement and Vn,steel = 0. If Vn,steel is required, then the program will back calculate a spacing, s, that will satisfy the steel shear capacity required. This shear spacing is reported in the detail report.

If Vn max must be exceeded to pass the code check, the program will use Vn max as the capacity (so the wall fails in shear) and state "Over Allowable" for the Shear Steel Spacing.

Note:

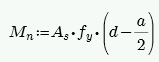

Lintel design in RISA does not account for axial force, thus Mn is calculated simply from:

Here are the calculations of other values reported in the detail report: